DTF Station 13" Prestige R2 Curing Oven and Miro 13 Max Shaker Bundle

($200 value)

. Added to cart automatically; remove to opt out. Enjoy lifetime setup, troubleshooting, and expert help—free!

Terms apply

($200 value)

. Added to cart automatically; remove to opt out. Enjoy lifetime setup, troubleshooting, and expert help—free!

Terms apply

Why Choose HeatPressNation?

With over 15 years of experience, HeatPressNation has established itself as the trusted industry leader in heat transfer solutions, earning the confidence of thousands of satisfied customers.

Flexible Financing Available

Flexible Financing Available

From Buy Now, Pay Later to our Monthly Payment Plans, we have a range of personal financing or business credit options available at checkout.

Thank you for your submission!

We will get back to you soon.

*Discontinued*

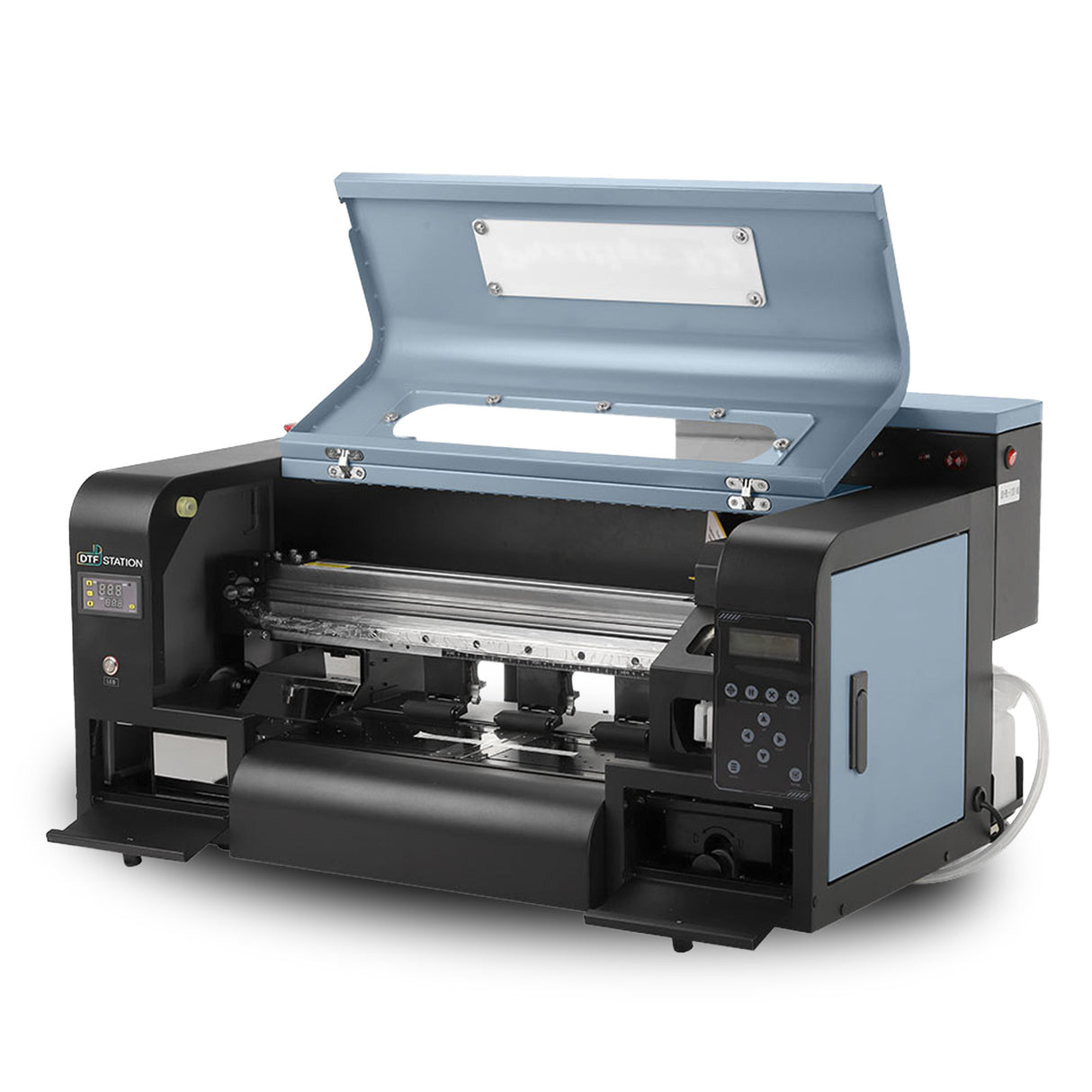

Print with precision and flair with the Prestige R2 DTF Printer! With its chic, integrated design, this printer combines elegant desktop convenience with powerful performance for all those looking to get started with DTF. Virtual Training is included with your purchase, or you can opt for On-Site Training for an additional fee.

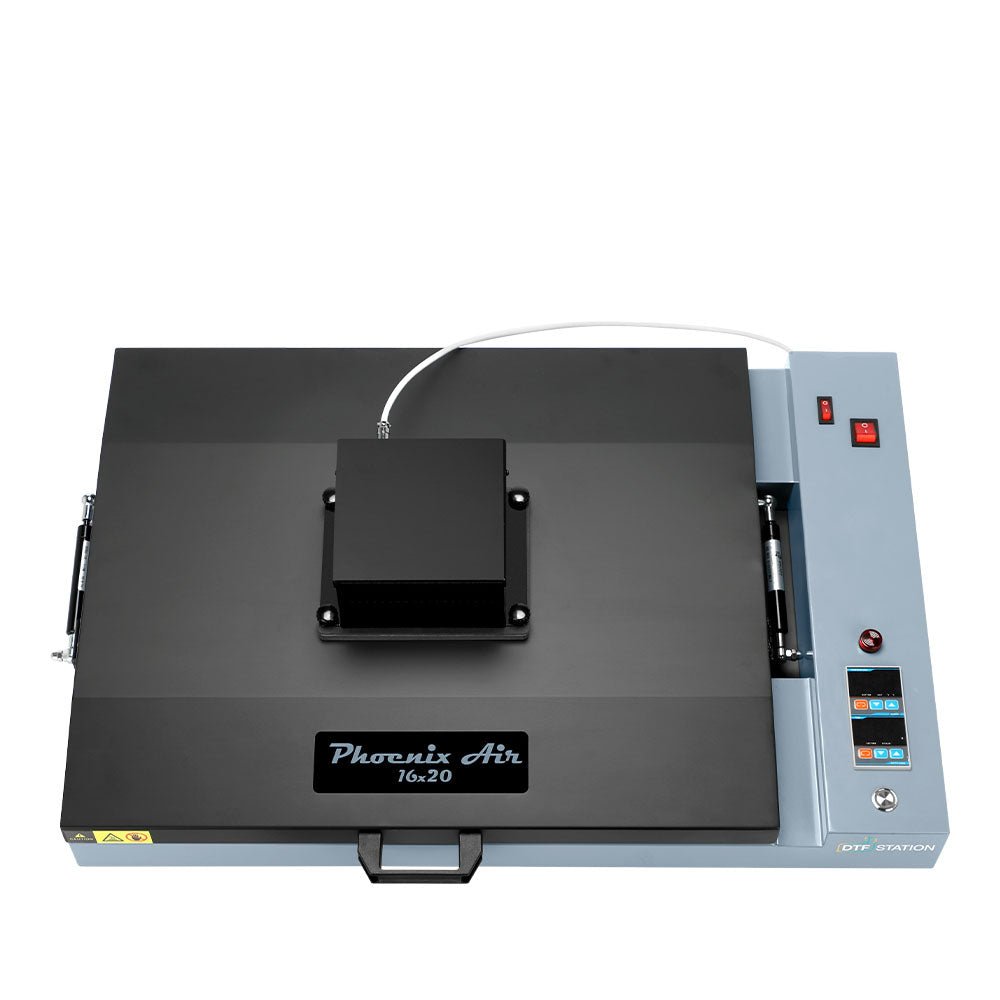

The DTF Station Phoenix Air 16" x 20" Curing Oven is a professional-grade curing oven designed specifically for DTF printing. With its built-in air purifier, it ensures a clean and efficient curing process, resulting in high-quality prints every time.

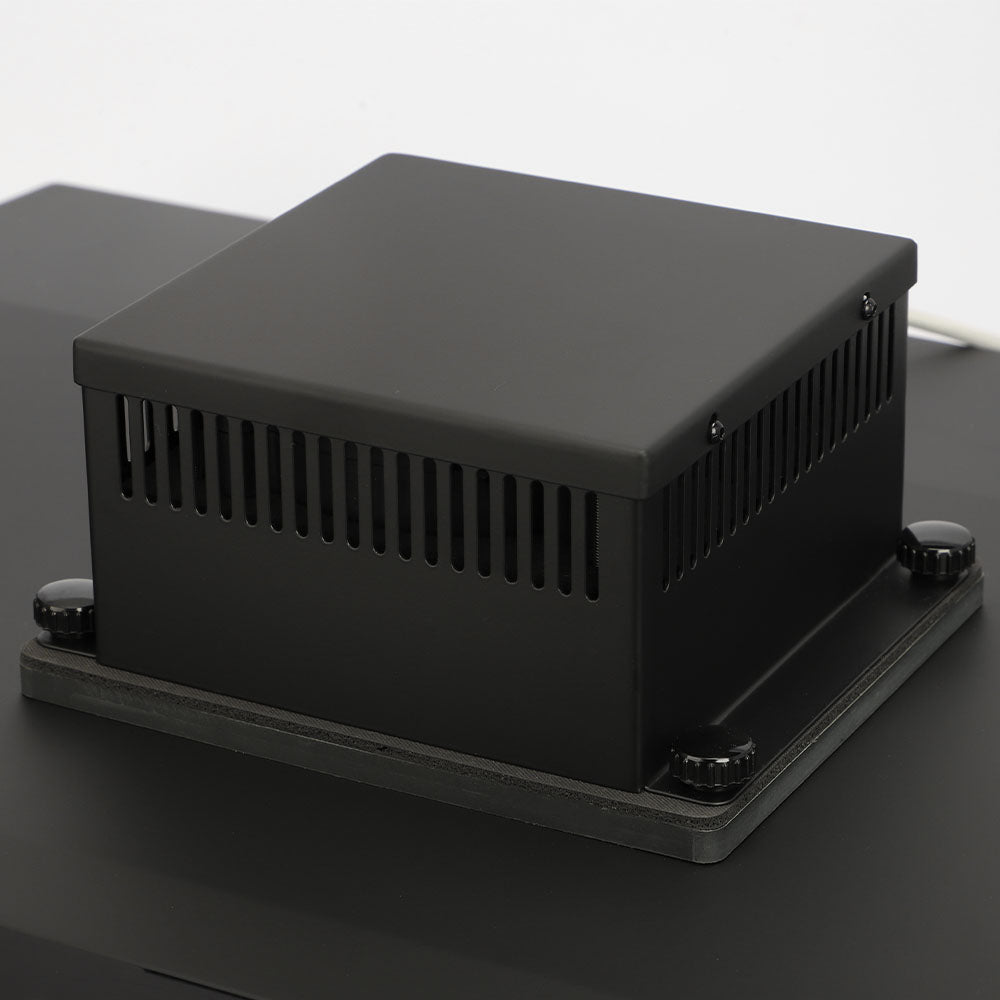

The Miro 13 Max is DTF Station's perfect powdering and curing solution for any A3 and A4 sized DTF printing setup.

With bottom platen heating for even, consistently cured transfers and a built-in air purifier for safer, more eco-friendly powdering, this shaker helps make powdering your DTF transfers a breeze. Plus, at just 1170W (1.17KW), this shaker requires no special electrical adjustments to install or use. Coupled with its intuitive interface and a suite of videos by DTF Station on how to install, use, and maintain the shaker, you'll be printing and powdering transfers in no time.

*Available for local pickup in California, call for availability*

Features and Benefits:

- Speed: 27 sq. ft/hour, 6pass

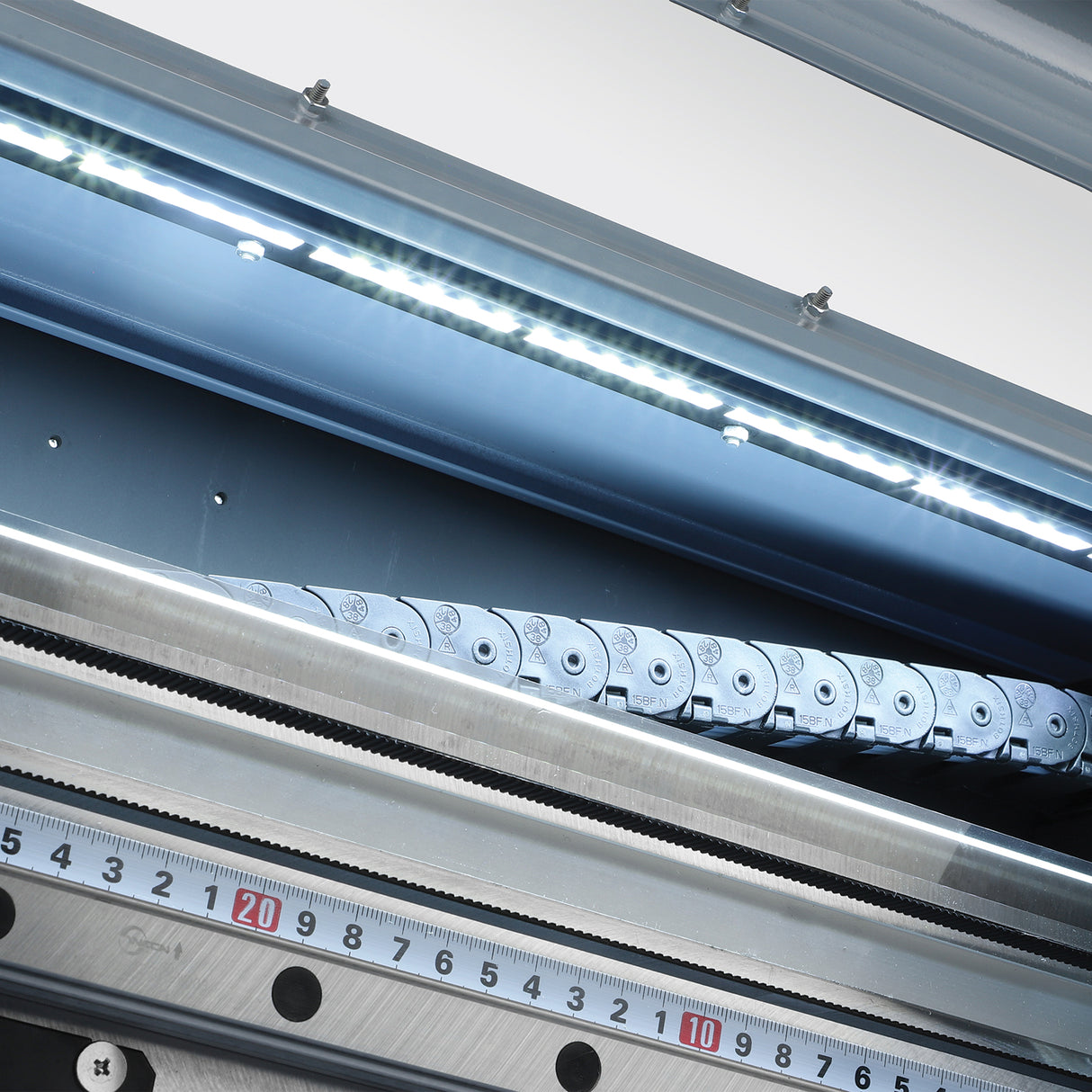

- White Ink Management System (WIMS): Timed white ink stirring system to circulate and maintain white ink inside the printer

- Passive Auto-Cleaning: When the printer is left on, it will automatically maintain and clean the printhead every 4 hours

- Active Auto-Cleaning: During set intervals (even during printing), the printer can stop to clean the printhead

- Head Strike Sensor: Helps prevent damage to the printhead

- 1 Liter Bulk Ink Cartridges: More ink for all your printing needs

- Auto Ink Alert System: Informs the user when ink is running low

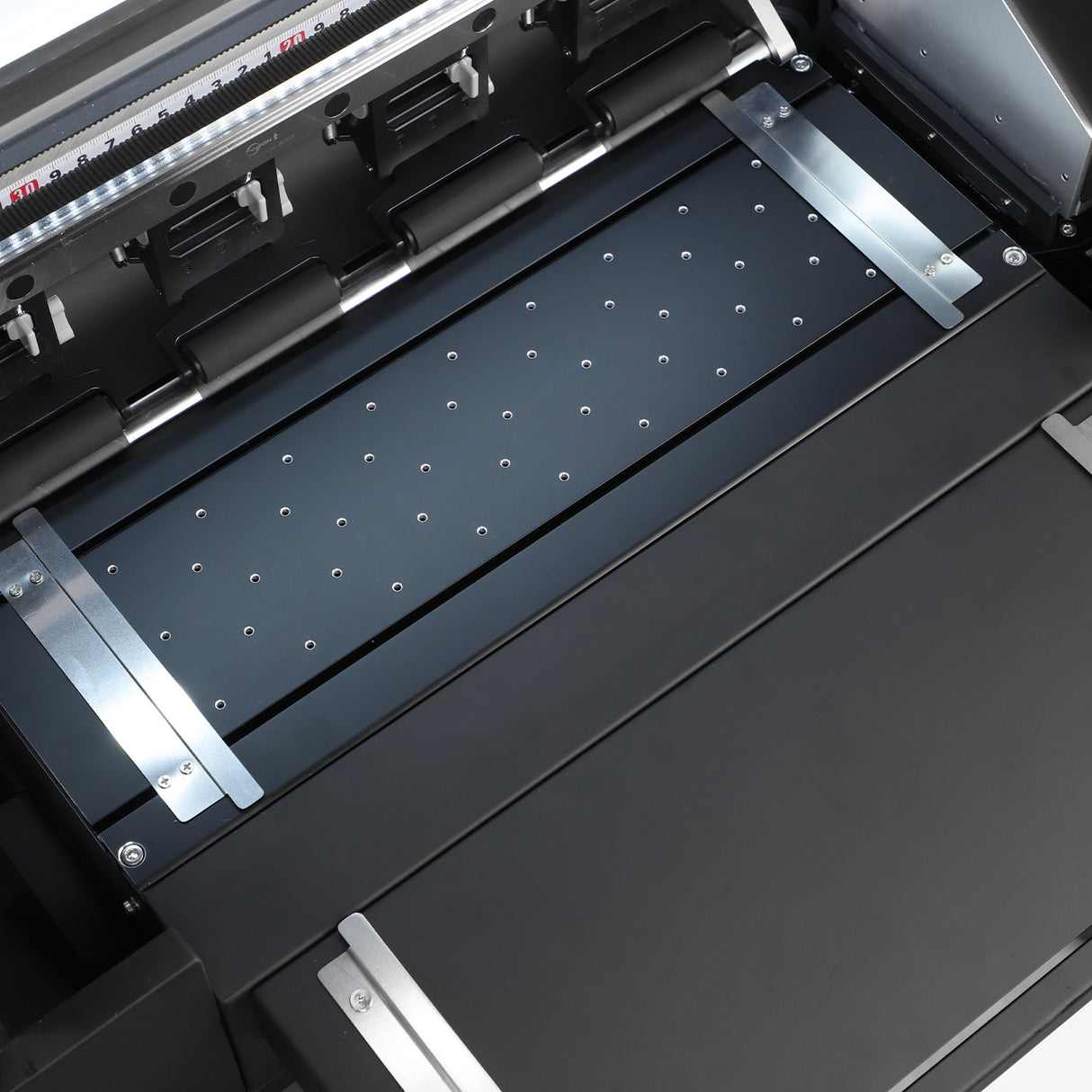

- Automatic Film Sensor: If film runs out/is not detected, stops printing

- Size: Desktop sized

- Great for Beginners: The perfect balance of power and affordability

- Easy Access/Repair: Intuitive, labeled board design and connections for easy access and repair

- Automated solution with DTF Station Miro 13 Max DTF Powder Shaker and Dryer

- Cure Transfers within a minute at 230~248°F

- Bottom Heating Element Rather than Top

- Self Contained Purification system

- Replace Filter 1~3 months depending on usage

- Digital Control Unit: easy to set & allows precise settings of temperature and time for consistent results

What's Included:

- DTF Station Prestige R2 DTF Printer

- DTF Station Phoenix Air 16" x 20" Curing Oven with Built-In Air Purifier

- DTF Station Miro 13 Max DTF Powder Shaker and Dryer

- neoStampa RIP Software

- Color Max DTF Pigment Ink (CMYKW) - 1kg (1 each)

- Color Prime Universal DTF Film Roll - A3+ (13") x 109 yd

- Color Prime Hot Melt Powder - 1kg

- DTF Station Cleaning Solution - 250 ml

- Free Lifetime US-based MyExpert Technical Support

- Live Virtual On-Boarding Class

- 300 Credits to the HPN Design Store

- Isopropyl Alcohol 16oz

- Lintless Wipe 4 x 4 30 Each

- DTF Station 7" Cleaning Swabs - 50 Each

- Power Cord

- Tools

- Ink Dampers

- Ink Filters

- Ink Tube

- Ink Diverter

- USB Dongle

- Ribbon Cables

- Screws

- Feed roller components

Not Included, but Also Needed:

-

Heat Press (used to press final print to garment - 16" x 20" recommended)

- Humidifier (to keep the humidity above 50% in the print room)

- Computer with Windows 10 or higher

Upgrading from the A4 model? See the DTF Station Trade-In Program for getting a credit.

Benefits of Direct to Film Transfers:

|

Any Color, Any Material: DTF transfers seamlessly adhere to multiple fabric types, regardless of color. Decorate cotton, nylon, polyester, leather, denim, and more. Unlock a world of vibrant possibilities for your designs! |

|

Easy to Use: Heat and pressure are all you need to transfer your designs. No need for pretreatment spray or tricky adhesive sheets. The transfer process is so simple that you can even sell your transfers for customers to apply themselves. |

|

Durable: Engineered to withstand the test of time, DTF transfers boast unparalleled durability, ensuring that your designs remain vibrant and intact through countless washes and wears. |

|

Soft and Stretchable: DTF transfers offer a silky-smooth touch and unparalleled stretchability, ensuring maximum comfort and freedom of movement with every wear. |

|

Long Shelf Life: With proper storage, DTF transfers can last for 1 year or longer. Print your more popular designs ahead of time, and press them on your schedule. |

Printer Specifications:

- Printer head: Dual Epson XP600 print heads

- Mainboard: Honson

- Interface: TCP

- Software: neoStampa RIP Software (Compatible with Windows Only)

- Max. Film Width: to 13" (33 cm)

- Print Speed: 27 sq ft / hour, 6pass

- Power Ratings: 700 Watts / 110 Volts / 6.36 Amps

-

Machine Weight: 110 lbs

- Machine Dimensions: 29" x 14" x 14"

- Shipping Weight: 142 lbs

- Shipping Dimensions: 32 1/4" x 15 3/4" x 15 3/4"

- Daily Output: 160 pcs (Based on design size as 12" x 14", 8 hrs per day)

Curing Oven Specifications:

- Voltage: 110V

- Power: 0.88KW

- Temperature Range: 0-150°C / 300°F

- Machine Size: 29"W x 21"D x 7.75"H

- Packaging Size: 31"W x 25"D x 10.75"H

- Product Weight: 30 lbs

- Packaging Weight: 35 lbs

- Warranty Policy

- Phoenix Air 16x20 Operation Manual

Shaker Specifications:

- Max Film Width: 13.78"

- Power Requirements: 110V, 1.17KW, 10.6A

- Product Weight: 70.6 lb

- Packaging Weight: 81.6 lb

- Product Dimensions: 40“D x 23.6“W x 18.5“H

-

Packaging Dimensions: 26.1”D x 23”W x 20.7”H

-

Warranty Policy

System Requirements

- Operating System: Windows

- Minimum RAM: 8GB

- Minimum CPU: Intel i5 2.6GHz

- Minimum Free Storage: 5GB

Note: It is recommended to turn on the air purifier ONLY while the oven timer is running. Leaving the air purifier on for prolonged periods may increase the overall temperature of the oven beyond recommended curing temperature.

The DTF Station Phoenix Air 16" x 20" Curing Oven is perfect for curing large film sizes, such as 13" x 19", 14" x 16", 16" x 20", and more! This oven has a built-in purifier unit to ensure your production space's safety. Additionally, the new lower heating system and gas spring lifting mechanism help ensure your prints cure with less power consumption and even heating.

Note: Unlike the previous DTF Station Phoenix 16" x 20" Curing Oven, the DTF Station Phoenix Air 16" x 20" oven uses an open-top/platform, rather than a tray, to cure films. See the DTF Station Phoenix A2 Curing Oven for similar heating methods.

WARNING: Work in a WELL VENTILATED AREA and use protective equipment when working with DTF products and processes. It is highly recommended the use of a Fume Extractor to handle the fumes caused by TPU adhesive powder curing. Bodily protection, including the use of PPE equipment such as a full body covering, a respirator / N95 mask, goggles and gloves are recommended to protect against TPU adhesive powder (prior to curing) that may become airborne due to handling. Inhalation of TPU adhesive powder or fumes may be hazardous to your health. The use of DTF equipment, chemicals, powders, inks and all accessories are at the sole risk of the user. DTF equipment is intended for use in a commercial environment. It is not recommended to use DTF equipment in a residential, or in-home setting. DTF inks and film require a good humidity environment - over 50% humidity is highly recommended to minimize the risk of ink clogs and film buckling. Add a Fume Extractor to this package for sufficient fume extraction.

DTF printers require daily use/maintenance! You must perform a head cleaning, nozzle check and a test print every day to ensure the printer is running smoothly and to prevent printhead and capping station clogs. Printheads and capping stations are considered consumables and are not covered under warranty if they clog. Clogs can occur even after one print, so maintenance must start the moment you install ink.

The HPN MyExpert Support guarantee is our commitment to Lifetime Technical Support. No matter where you are in your product's life cycle, we will be here to provide support to your product and make sure you are fully covered.

Our MyExpert Support will always be there for you so you can purchase with confidence!

In addition, DTF Station, the manufacturer, offers a conditional 1-Year warranty on up to 2 printheads. Full printhead warranty policy. For warranty claims, we may need to involve the official DTF Station team depending on the reported issue. Be aware that the use of non-DTF Station ink, film, or other supplies will void the warranty. Details depend on training option selected. Terms & Conditions apply. Visit link for full details.

The HPN MyExpert Support guarantee is our commitment to Life Time Technical Support. No matter where you are in your products life cycle, we will be here to provide support to your product and make sure you are fully covered.

Often imitated, never duplicated; our dedicated team of technicians are capable of providing support to your product at any point of its life. Whether it be during the setup process or even years down the line where troubleshooting may be required, they'll have your back and provide a solution.

Our MyExpert Support will always be there for you so you can purchase with confidence!

In addition, all HPN branded heat press machines come with a 1 Year Parts and Service Warranty from the original date of purchase. We carry all parts necessary to complete warranty service with the speed and efficiency that your business deserves. Warranty service does not include the cost of freight of the item to or from our facilities. If parts and/or accessories are needed at any time during the warranty period, Heat Press Nation will send them to you at no charge upon receipt of the defective part. Once the warranty period has ended, parts will be available at market price.

For Non-HPN branded machines, the duration of warranty will vary. This will be in the description section itself or can be verified with our MyExpert team if it unclear.

Extended Warranty for HPN Branded Machines

Protect your investment by extending the manufacturer's parts and service warranty.

HeatPressNation's MyExpert Protection keeps your device covered when bad luck happens. We'll work with the manufacturer to makes sure you receive the correct replacement parts and service for your product.

PLANS

- 1 Year Total Coverage - Included with purchase

- 2 Years Total Coverage - $49.99

- 3 Years Total Coverage - $79.99

- 4 Years Total Coverage - $99.99

Add "MyExpert Protection" when adding your product to the cart

The HPN MyExpert Support guarantee is our commitment to Lifetime Technical Support (A $200 Value included with your purchase). No matter where you are in your product's life cycle, we will be here to provide support to your product and make sure you are fully covered.

Often imitated, never duplicated; our dedicated team of technicians are capable of providing support to your product at any point of its life. Whether it be during the setup process or even years down the line where troubleshooting may be required, they'll have your back and provide a solution.

Our MyExpert Support will always be there for you so you can purchase with confidence!

We're here to help you with:

- Technical Support

- Equipment Consultations

- Troubleshooting

- Business Tips

- & More!